Monday, January 25, 2021

January 25, 2021

January 25, 2021 Abdul Hameed

Abdul Hameed Terminology

Terminology No comments

No comments

Wednesday, January 20, 2021

January 20, 2021

January 20, 2021 Abdul Hameed

Abdul Hameed Over View

Over View No comments

No comments

What is a Pump ?

Types of Pumps

Pump types generally fall into two main categories - Dynamic (Centrifugal) pump

- Positive Displacement pump

PUMP CHARACTERISTIC

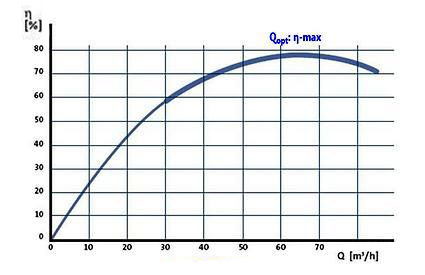

PUMP EFFICIENCY

Unstable & Drooping

Shutoff Head

Shutoff Head

The shut-off head of a pump is at where the flow rate in a vertical pipe connected

to the operating pump becomes zero.

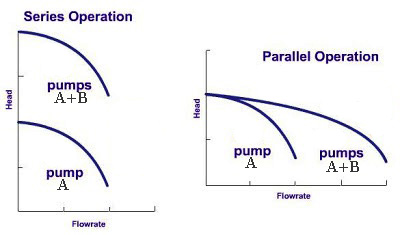

Series & Parallel Operation

Affinity Laws

Q1/Q2 = (N1/N2) or (D1/D2)

H1/H2 = (N1/N2)2 or (D1/D2)2 P1/P2 = (N1/N2)3 or (D1/D2)3 Q = Flow, N = shaft speed RPM, D = Impeller diameter, H = head, P = power

Head & Pressure Relationship

Monday, January 18, 2021

January 18, 2021

January 18, 2021 Abdul Hameed

Abdul Hameed About me

About me No comments

No comments

A giant ship engine failed. The ship’s owners tried one expert after another, but none of them could figure but how to fix the engine.

Then they brought in an old man who had been fixing ships since he was a young. He carried a large bag of tools with him, and when he arrived, he immediately went to work. He inspected the engine very carefully, top to bottom.

Two of the ship’s owners were there, watching this man, hoping he would know what to do. After looking things over, the old man reached into his bag and pulled out a small hammer. He gently tapped something. Instantly, the engine lurched into life. He carefully put his hammer away. The engine was fixed!

A week later, the owners received a bill from the old man for ten thousand dollars.

“What?!” the owners exclaimed. “He hardly did anything!”

So they wrote the old man a note saying, “Please send us an itemized bill.

The man sent a bill that read:

Tapping with a hammer………………….. $ 2.00

Knowing where to tap…………………….. $ 9,998.00

Effort is important, but knowing where to make an effort makes all the difference!

January 18, 2021

January 18, 2021 Abdul Hameed

Abdul Hameed Positive displacement

Positive displacement No comments

No comments

Positive Displacement Pump

Classification:

January 18, 2021

January 18, 2021 Abdul Hameed

Abdul Hameed Centrifugal

Centrifugal No comments

No comments

Classification of Centrifugal Pump